Search

Our priorities mirror India’s Viksit Bharat goals

VG Sakthikumar, Chairman and Managing Director, Schwing Stetter India, speaks on the growth priorities for the Indian market in the next three to five years.

Lifting India’s Future

As India builds faster and taller, industrial cranes are emerging as essential, intelligent machines powering the nation’s infrastructure, logistics, and industrial growth.

Lifting India’s Future

As India builds faster and taller, industrial cranes are emerging as essential, intelligent machines powering the nation’s infrastructure, logistics, and industrial growth.

The crane market is expected to see consistent growth

Arvind Rishi, AVP – Sales & After Market, TIL Limited, speaks about the evolving demand for industrial cranes driven by the rise in industrial projects in India, and how safety features are increasingly being incorporated into these cranes.

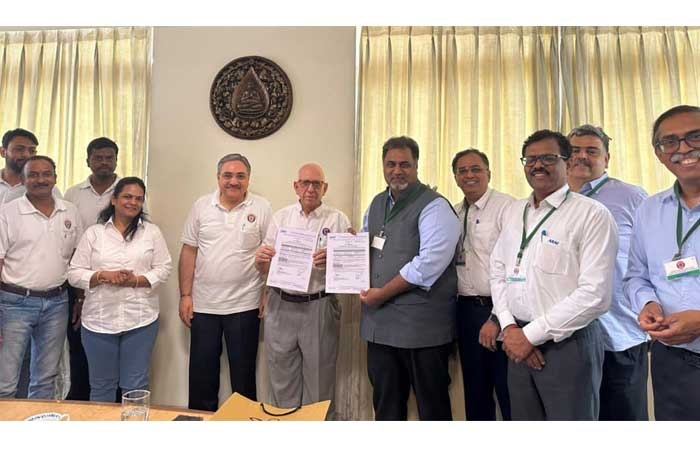

Altair and ARAI partner for technology advancement

Altair, a global leader in computational intelligence, announced it has signed a memorandum of understanding (MoU) with the Automotive Research Association of India (ARAI) to foster technology and digital transformation within the automotive and heavy engineering sectors.

Altair and ARAI partner for technology advancement

Collaboration will showcase digital twin technology, data-driven design, and AI-powered engineering

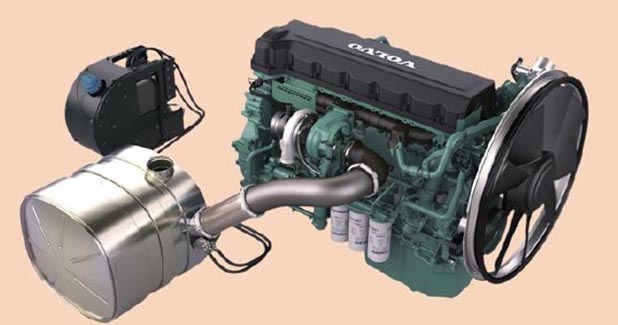

Cooper Corp’s diesel engines get ARAI stamp of approval

Cooper Corporation, based in Satara, Maharashtra, celebrates ARAI certification for its Diesel Engines, affirming compliance with CPCB IV+ emission regulations.

The Concrete Revolution

Groundbreaking concrete equipment is driving the industry forward at an unprecedented pace.

India’s CE market is growing rapidly due to urbanisation

KYB Conmat, one of the leading global concrete equipment manufacturers, produces concrete batching plants, paving machines, pumps, transit mixers, and self-loading mixers. Kalpesh Soni, Vice President, Marketing, KYB Conmat, speaks on the recent innovations and advancements in their product line.

We pioneered the introduction of battery electric wheel loaders in India

SDLG India, a member of Volvo Group, is a leading provider of construction equipment solutions, emphasising innovation, reliability, and affordability. Its range includes wheel loaders, excavators, motor graders, and more. Surat Mehta, Head of SDLG Business in India, speaks about the company’s newly inaugurated manufacturing facility in Bengaluru and how it has enhanced the company’s capabilities in serving the Indian market.

We are also growing in the concrete pump segment

KYB Conmat, with over 13 years of experience in the industry, is one of India’s leading manufacturers of concrete equipment and holds a top three position in most segments, including batching plants, paving machines, transit mixers, and self-loading mixers. Kalpesh Soni, Vice President – Marketing, KYB Conmat, speaks on how his company is hearing up for Excon 2023.

The New Concrete Frontier

Contractors must adopt advanced, efficient concrete equipment to meet growing project sizes, tight deadlines, and high-strength concrete demands.

We will display our range of self-loading concrete mixers

Kalpesh Soni, Vice President, KYB Conmat, discusses the various challenges faced by the company.

L&T compactors are very well established in the Indian market

L&T’s Construction and Mining Equipment business manufactures, distributes and provides after-sales support for construction and mining equipment for diverse industries and applications.

Road Equipment: Road to Recovery

The Ministry of Road Transport and Highways (MoRTH) has big plans of constructing expressways, national highways, state highways and rural roads in the coming years. However, any uncertain economic situation in future may affect the recovery of the market as this will affect the payment of contractors, financing and thus equipment mobilisation.

Compliance Challenges

Embracing the next level emission regulations is expected to be tough for the engine and equipment OEMs considering technology upgradations and need for adequate skill development among the users.

Loads of Opportunities

With the construction activity picking up and mining operations reviving in India, new opportunities are knocking at the doors of the wheel loader market.

"Customers NOW prefer higher capacity equipment"

With the impending revival of infrastructure sector and the government's definitive focus on growth, sales are expected to rise in the coming days.

Emission certified gas gensets

Cooper Corporation is amongst the first in the industry to get an approval from Automotive Research Association of India (ARAI) to develop a series of gas generator sets (gensets) ranging from 10 KVA to 25 KVA.

Cooper Corp to produce ARAI approved gas gensets

Cooper Corporation is amongst the first in the industry to get approval from Automotive Research Association of India (ARAI) to develop a series of gas generator sets (gensets) ranging from 10 KVA to 25 KVA. These are certified to be compliant with the new mass emission norms being administered by the Central Pollution Control Board (CPCB) in India.

Earthmovers from SEM

With the increased government spend on infrastructure projects, more and more new players are entering into the market and taking up smaller contracts. These customers are on the lookout for ready-to-run (reliable and affordable) products at an affordable price.

Lubricants market in India is getting more lucrative

The expected robust demand for construction equipment and machinery is going to generate a concomitant demand for industrial and construction machinery lubricants in India. Akhil Jha, Chief Technology Officer, Shell Lubricants India, explains more on the new trends and product innovations in lubricants.

Back on Growth Path

Given its versatility and mobility, backhoe loader finds great use at almost every construction site, both urban and rural India. This multi-purpose machine continues to perform a variety of tasks at sites and is used for digging, dosing, levelling and lifting activities.

Motor Grader GR 150

The GR 150 can be used in various applications such as road building, cutting a ditch, earthmoving or fine grading. Schwing Stetter has launched the GR150, a 150 hp motor grader at Excon 2015. Being an ARAI certified product, it can be used in various applications such as road building, cutting a ditch, earthmoving or fine grading.

Essential for Road Building

Commitment towards infrastructural development and faster implementation of road projects to desired specifications are driving the growth of the motor grader market in India.

Convert your surplus assets into cash

It takes special expertise to get the best value to owners from the sale of surplus assets. Quippo has designed an auction platform to buy and sell construction and mining equipment, commercial vehicles, industrial assets, plant and machinery, scrap and more, ensuring our customers and clients get the best asset valuation and highest return from auctions.

Wheel Loaders and Motor Graders

Schwing Stetter offers its new range of wheel loaders and motor graders. Wheel loaders are offered in two models while motor grader come as model GR 150.

Pick-n-Carry Hydra: Bestseller

As the Numero Uno bestselling lift and reach product, Hydra crane still continues to be the most demanding mobile crane category in India. Tyre-mounted articulated steering, hydraulic mobile pick-and-carry crane, colloquially termed ?Hydra?, was introduced in India

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com